GRS Automation

Precision-Driven Engineering

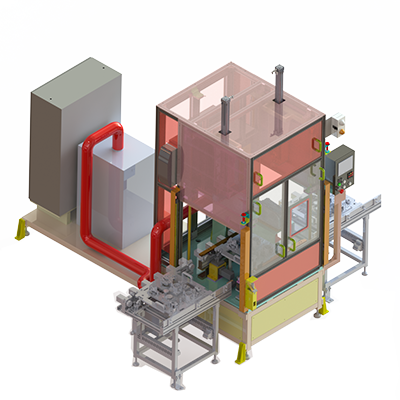

At GRS AUTOMATION, we deliver turnkey solutions for special purpose machines—driven by deep domain expertise and a commitment to process excellence. Our core capabilities include engineering design, automation, engineering analysis, piping engineering, product development, manufacturing services, and detailed engineering.

We are the leading manufacturer and supplier of Leak Testing Machines, Laser Marking Machines, Process Checking, Metal Detectors, Industrial Automation and Conveyor Systems.

Based in Bengaluru – Serving Pan‑India

Headquartered in the tech‑hub of Bengaluru, GRS Automation is strategically positioned to serve domestic and international clients. We possess both the infrastructural strength and logistical capability to manage projects across India reliably.

Partner with GRS Automation to unlock productivity gains, reduce defect rates, and accelerate production cycles. From leak test setups to laser marking lines and conveyor automation, we curate solutions tailored to your KPIs.

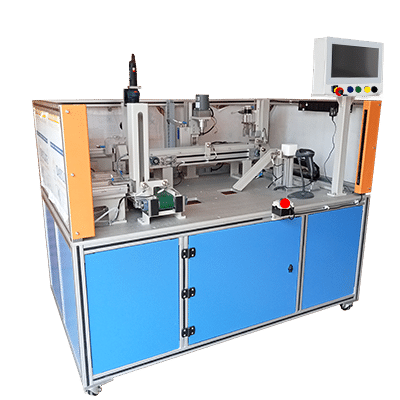

Laser Marking

Laser marking is a non-contact, permanent process that employs a highly focused beam of light to produce precise and durable marks on a variety of surfaces.

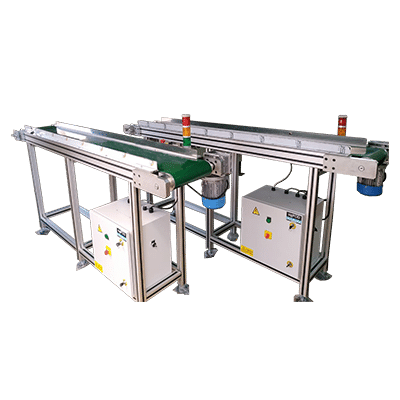

Conveyors

A conveyor system is a highly efficient automated material handling solution, essential for transporting components & products within manufacturing facilities.