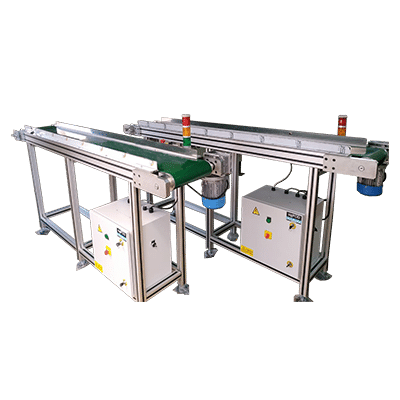

Conveyor

Bridging Processes with Precision

These systems significantly reduce human error, enhance safety, and lower labor costs by automating the movement of parts and assemblies. In the automotive industry, where precision and speed are critical, conveyor systems help streamline production processes and improve throughput.

At GRS Automation, we manufacturer the following types of conveyor systems are commonly used in automotive manufacturing:

Power & Free, Gravity, Tsubaki Roller Conveyors: Typically used for transporting heavy or bulky components such as chassis, car bodies, and large automotive parts. Roller conveyors facilitate smooth, friction-free movement, which is ideal for high-volume production lines. Powered or gravity roller systems are widely employed in assembly lines and component staging areas.

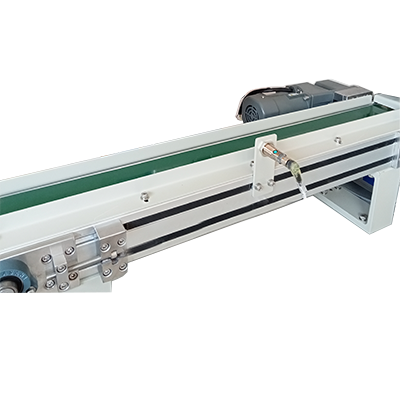

Belt Conveyors: Frequently used in automotive assembly lines for tasks such as part feeding, assembly, and quality inspection. Belt conveyors provide continuous transport of smaller or lighter components, ensuring that parts move seamlessly from one workstation to the next. This system is also highly adaptable, capable of handling various types of products, including tires, seats, and electronics.

+ Write to Know More