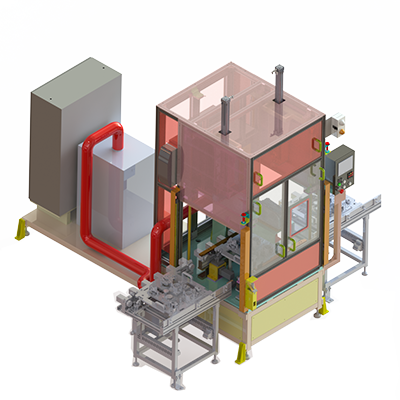

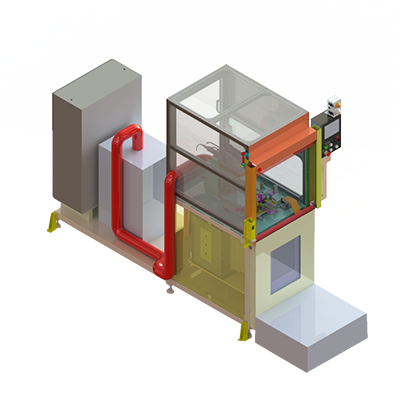

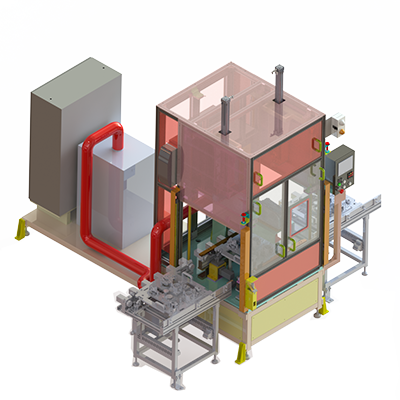

Laser Marking Machine

Marking with Unmatched Accuracy and Durability

Typically executed using advanced laser systems such as fiber lasers, pulsed lasers, continuous wave lasers, green lasers, or UV lasers, this technique allows for high-speed, automated processing with minimal thermal impact on the surrounding material.

Laser marking is suitable for a wide range of substrates, including metals like steel, titanium, aluminum, and copper, as well as non-metals such as ceramics, plastics, glass, wood, paper, and cardboard.

We design and build Laser marking machines which are capable of producing various types of marks, such as alphanumeric text (including serial numbers, part numbers), machine-readable identifiers (barcodes, 2D Data Matrix codes, QR codes), and unique identification codes. This ensures reliable and permanent traceability, with high precision and repeatability, making laser marking an ideal solution for applications requiring high throughput and stringent traceability standards in industries like automotive, aerospace, medical devices, and electronics.

+ Write to Know More